by Chris Okula | Jan 11, 2024 | Overhauls and Turnarounds

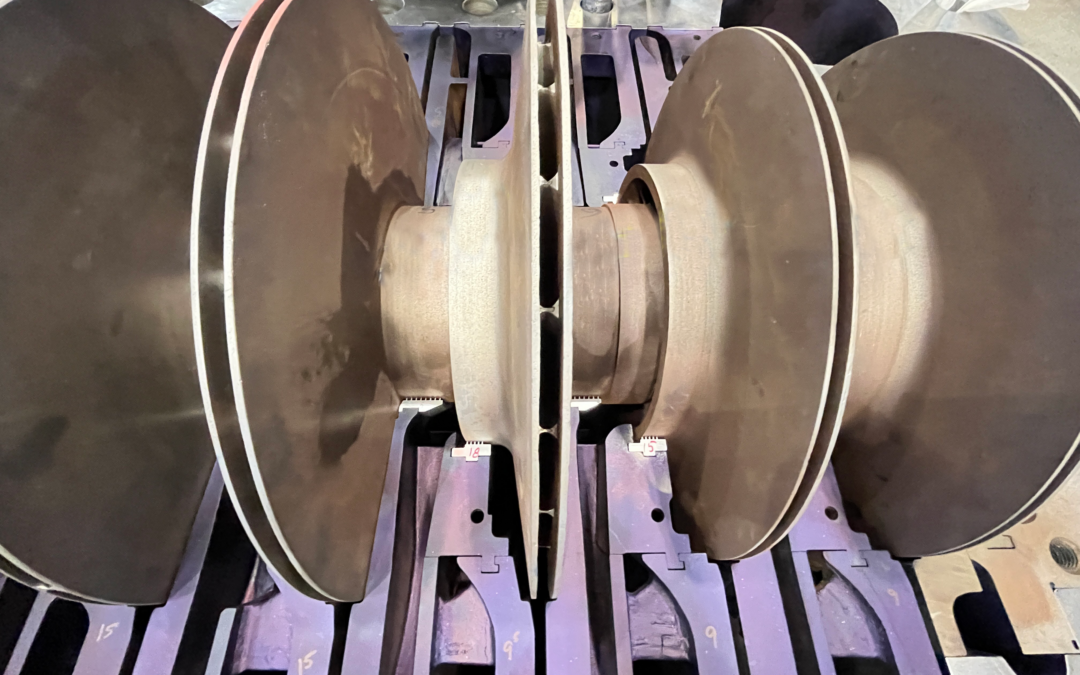

RMS worked with a world-class plastics manufacturer to support the upgrade and overhaul of their DH Single-Stage AC Compressor Centrifugal Compressor. This AC Compressor DH compressor was critical to the customer’s manufacturing process so RMS needed to execute at a...

by Chris Okula | Jan 4, 2024 | Overhauls and Turnarounds

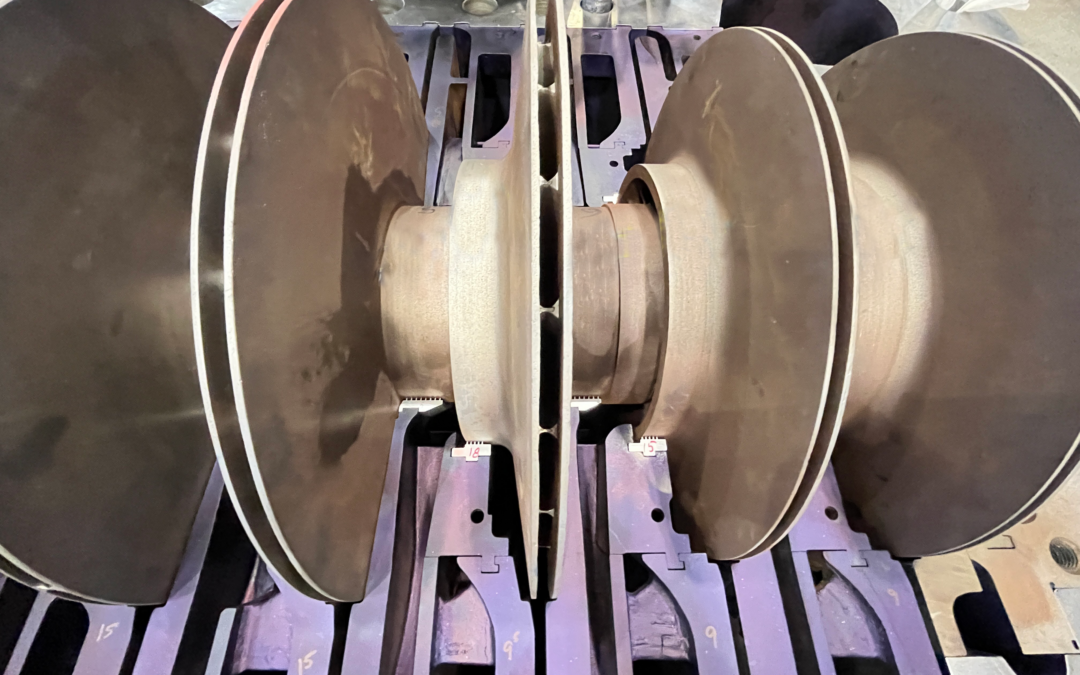

RMS was contacted by a refining customer to support the overhaul of an AC Compressor V-405 centrifugal compressor. RMS conducted the entire overhaul operation at the RMS Pearland Works facility where the team worked to deliver this overhaul ahead of schedule. In...

by Chris Okula | Dec 18, 2023 | Overhauls and Turnarounds, Recent Projects

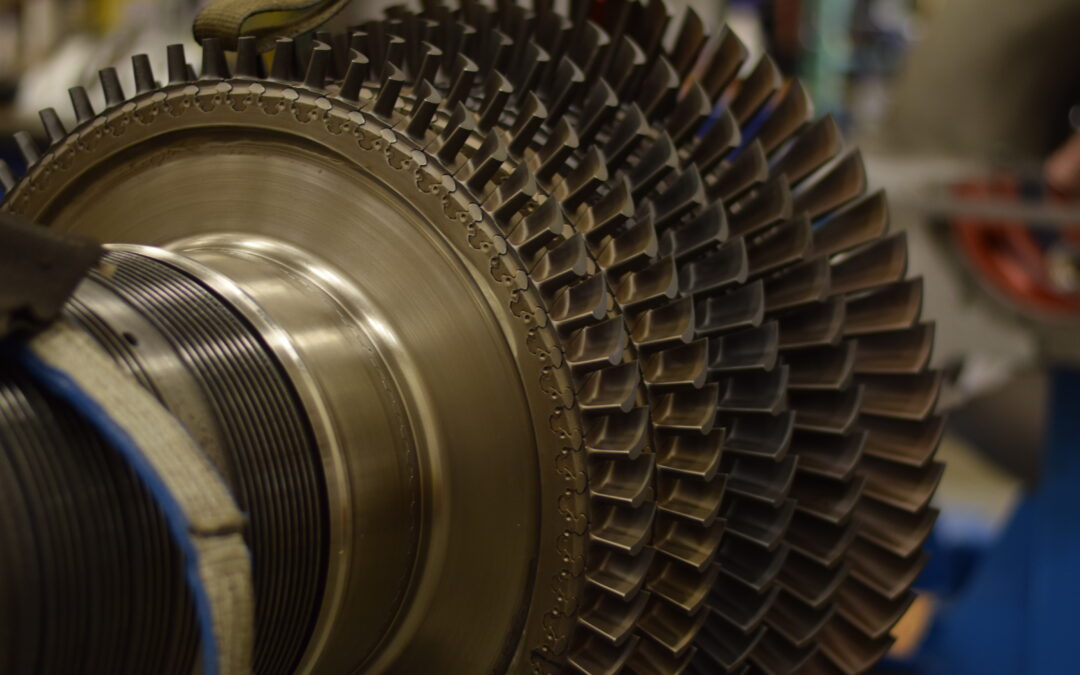

RMS was contacted to support a customer with an emergency outage of their Elliott 38M centrifugal compressor. This refining customer experienced a failure that caused water to enter the casing during operation leading to an emergency shutdown. RMS field service was on...

by Chris Okula | Aug 21, 2023 | Metrology, Overhauls and Turnarounds

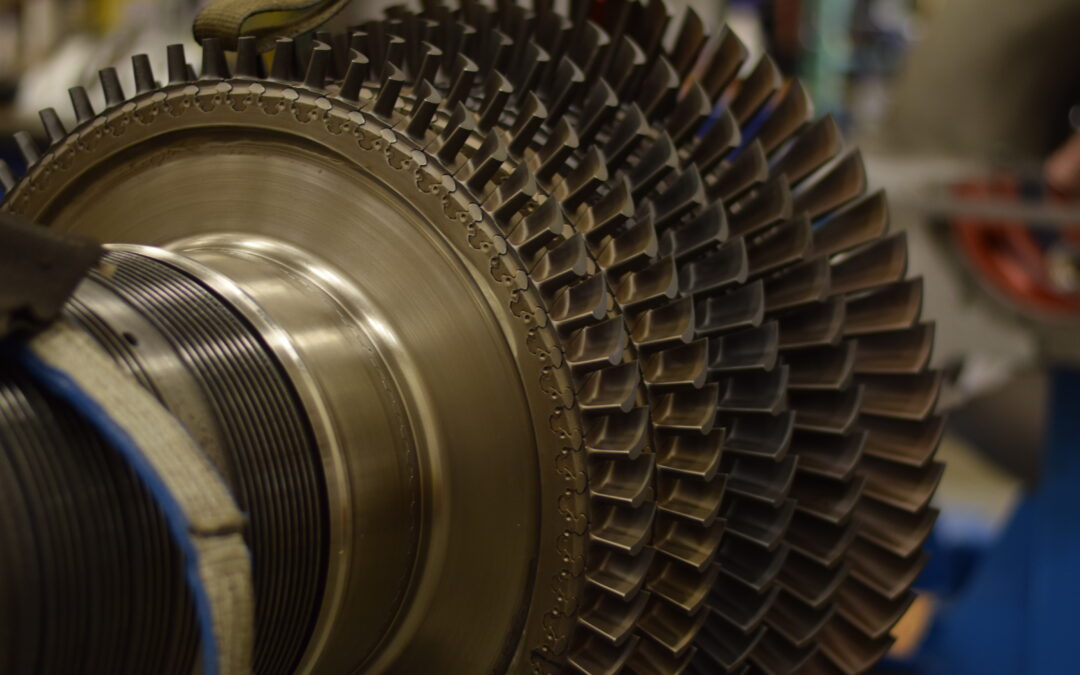

RMS recently completed a successful turnaround of an Elliott 29MBH3 centrifugal compressor for a refining customer. This critical turnaround required precise coordination of the RMS shop, engineering team, and metrology team to execute ahead of schedule. During the...

by Chris Okula | Mar 7, 2023 | Overhauls and Turnarounds

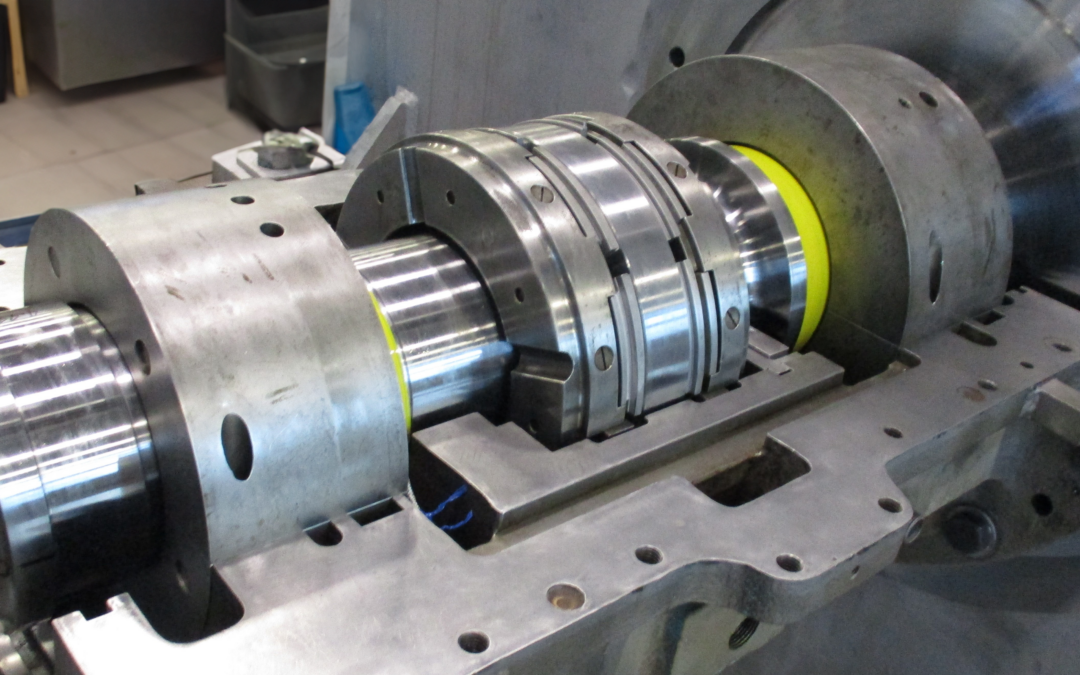

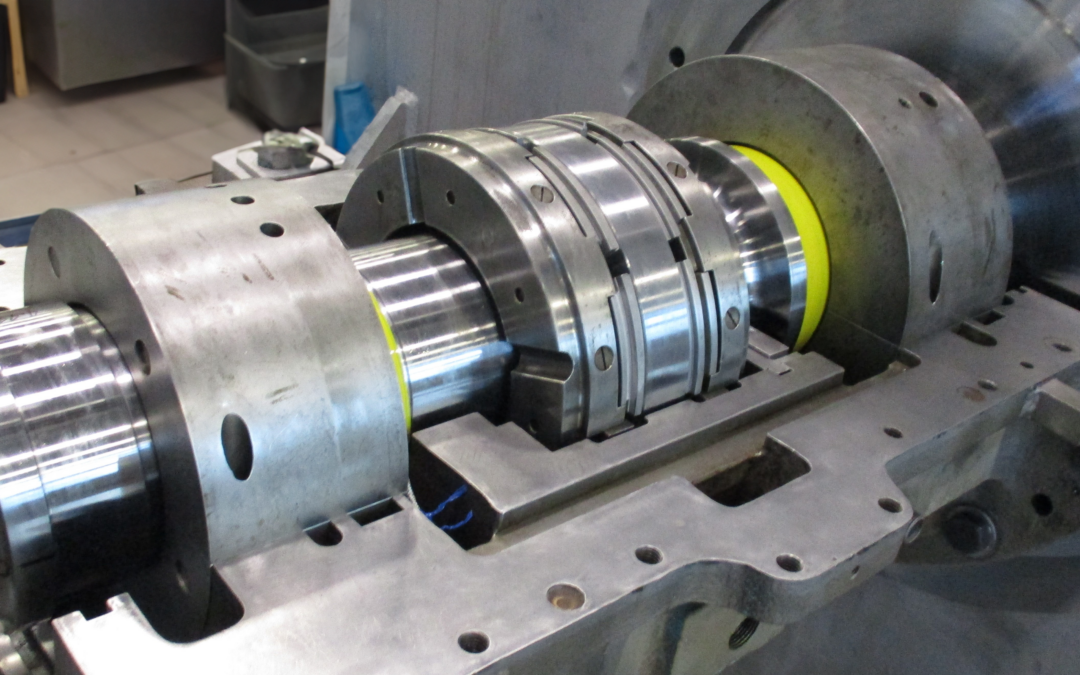

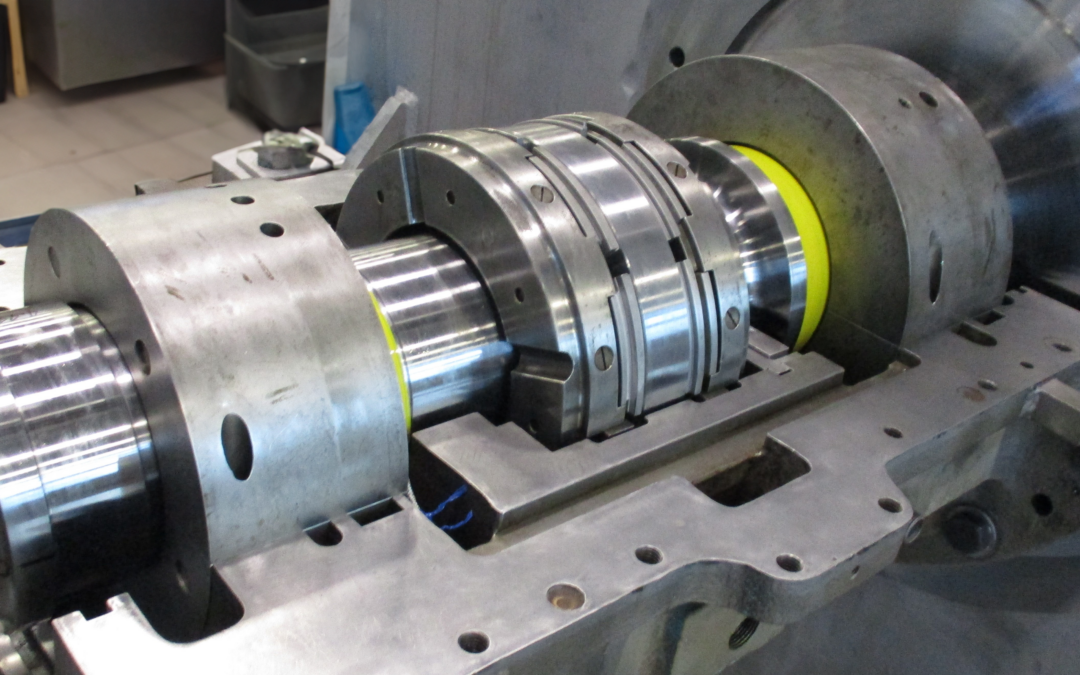

A petrochemical customer experienced a bearing failure in their Dresser-Rand Axi 630HS165 Oil Free Screw. The customer contacted RMS to discover and address the root cause of this failure and repair their oil free screw compressor with goal of promptly to restoring ...

by Rotating Machinery | Jan 12, 2021 | Overhauls and Turnarounds

RMS’s decades of experience supporting Multi-OEM Nitric Acid Expanders are a key component in our ability to offer industry-leading engineered solutions. Nitric Acid Expanders are critical pieces of machinery that undergo punishing conditions during operation making...