RMS was contacted to support a customer with an emergency outage of their Elliott 38M centrifugal compressor. This refining customer experienced a failure that caused water to enter the casing during operation leading to an emergency shutdown. RMS field service was on the scene to support the removal of the compressor. The compressor was sent to RMS’s Pearland Works facility where the RMS shop staff worked around the clock to get the customer’s site back online.

Upon arrival at RMS Pearland Works, the shop team immediately got to work disassembling the compressor for inspection. Due to the nature of the failure RMS had to use hydraulic torque wrenches to remove the bolts on the casing split line. The team was able to open the casing and get to work on inspections.

The compressor’s bearings and seals were sent out for expedited repair work using local vendors to cut down on lead times for the turnaround. New labyrinth seals were manufactured on an expedited basis so the RMS shop team could get them installed as soon as possible.

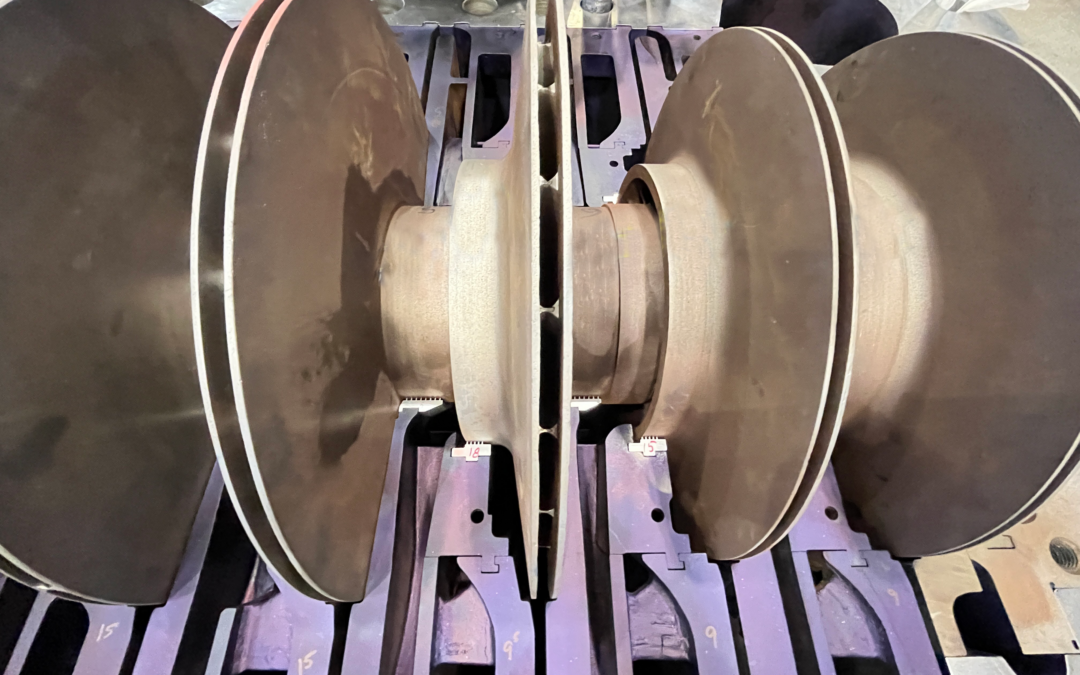

The customer sent RMS the spare rotor for the compressor for inspection and evaluation. The spare rotor was low-speed balanced by RMS and ready to place into the compressor casing. RMS completed all required repairs on the flow path and reassembled the compressor.

The Elliott 38M compressor was sent back to the customer using expedited shipping. Upon arrival, RMS’s Field Service team was on site to support the installation of the overhauled compressor. The RMS team was able to quickly turnaround this repair for the customer to get their site back online.