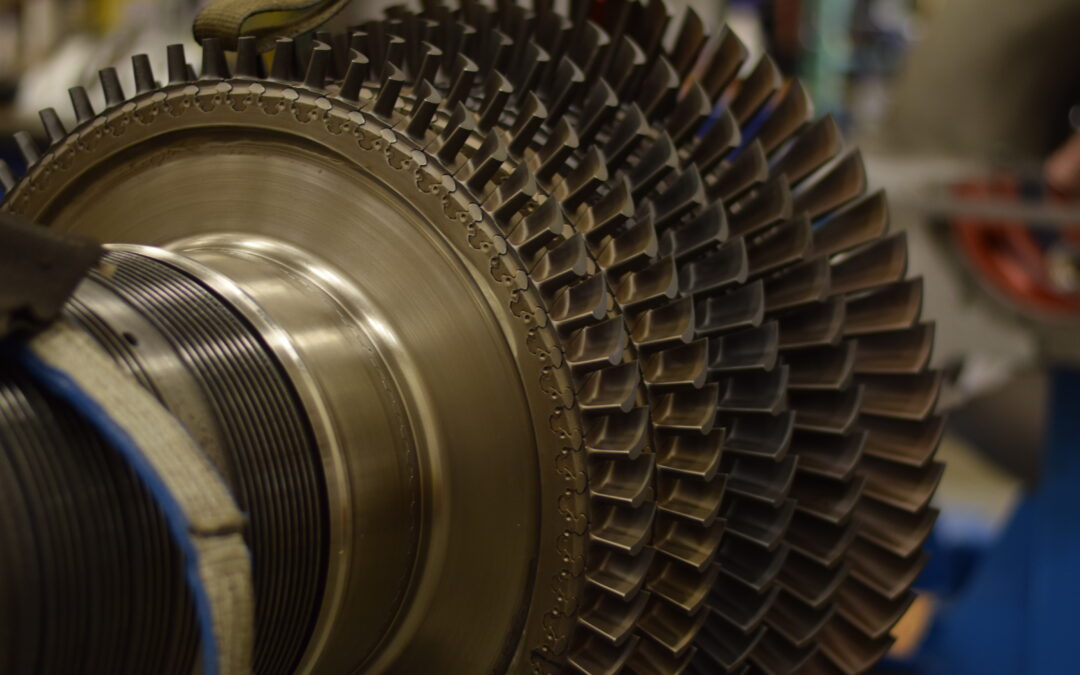

RMS’s decades of experience supporting Multi-OEM Nitric Acid Expanders are a key component in our ability to offer industry-leading engineered solutions. Nitric Acid Expanders are critical pieces of machinery that undergo punishing conditions during operation making it crucial that all repair and maintenance work is conducted with the highest quality. RMS understands what is required to keep your Nitric Acid Expander running at peak performance during its extensive service intervals and our experience and attention to detail are essential to a successful build and run.

Multi-OEM Capabilities

Thanks to a deep catalog of engineering expertise and stock of advanced hardware and software, RMS offers its engineered solutions for all expander nameplates. RMS is not a replicator. Our work is backed by sound engineering practices and fundamental knowledge of turbomachinery. Each manufacturer has its own designs and every expander is designed for its specific application. Although each Nitric Acid Expander is unique, expanders are designed with the same principles and operate under the same laws of nature. The ability to reverse engineer components and complete machines allows RMS to support the industry with our engineered solutions tailored specifically for your expander.

Overhaul and Engineered Repairs

With an experienced team of assembly mechanics, balance techs, machinists, and welders lead by our engineers, RMS is capable of completing the vital repairs needed to overhaul your Nitric Acid Expander. RMS offers repairs on all components including Inner and Outer Casings, Rotors, Stators, and Seals as well as Specialty Curvic grinding. Expert rotor and machine assembly complete RMS’ portfolio of Nitric Acid Expander repair offerings. Before implementing a Nitric Acid Expander repair or modification, RMS can inspect and analyze components to determine a reliable and cost-effective solution. Using advanced inspection and scanning tools, experienced QC personnel can gather critical data that allows our engineers and designers to recommend repairs and replacements to keep your expander running at peak reliability and efficiency.

Analysis, Upgrades, and Rerates

RMS leverages its advanced engineering capabilities to analyze, rerate, and upgrade existing Nitric Acid Expanders to better match ever-changing customer needs. Thanks to experienced engineers and cutting-edge modeling software in the disciplines of Aerodynamic, Thermodynamic, Structural, Vibration, Metallurgical and Rotordynamic analyses, RMS can modify the Power, Flow, and speed of an existing expander and offer material improvements. RMS is also capable of upgrading your expander for greater reliability, efficiency, and control as well as providing failure and remaining life analyses.

Turnarounds

RMS is capable of providing Nitric Acid turn around support both in the shop and in the field lead by an experienced RMS Field Supervisor to oversee the operation. We offer assistance during every phase of a turnaround starting at the early stages of planning, daily reporting, and progress updates and ending at the final commissioning and start-up.

RMS is committed to accessibility and responsiveness. Customers can contact any of our sales force, engineers, and project managers to get an immediate response. RMS is here to serve all of your Nitric Acid Expander needs with our commitment to quality engineered repairs leading the way. From engineering studies to complete overhauls, RMS is ready to support your Nitric Acid Expander. To learn more about how RMS can serve your Nitric Acid Expander needs, contact your local RMS Sales Representative.