Rotating Machinery Services (RMS) proudly announces the integration of Blading Services Unlimited (BSU) into its distinguished family of companies.

This strategic union is a testament to the commitment to excellence and marks a pivotal moment in the turbomachinery industry, combining the exceptional capabilities of BSU with RMS’ legacy of global engineering, repair, and maintenance services on critical compression equipment.

The collaboration with BSU brings together a wealth of skills, expert personnel, and longstanding customer relationships, reinforcing RMS’ dedication to providing top-tier aftermarket upgrades, repair, maintenance, and rebuilding/overhaul services for sophisticated turbomachinery. Having worked seamlessly alongside BSU for years, this integration promises a smooth transition and the delivery of outstanding customer service and innovative solutions.

BSU has rightfully earned a reputation for its exceptional quality, timely delivery, and exemplary customer service in the marketplace. We extend a warm welcome to Steve Stevens and the entire BSU team, whose expertise and dedication will further enhance the collective strength of RMS. This integration opens up new opportunities for us to provide a comprehensive suite of services to our valued customers, meeting all their turbomachinery requirements with precision and efficiency.

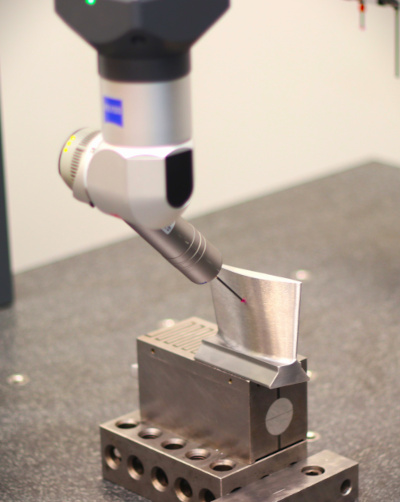

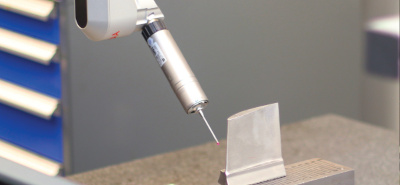

As an independent aftermarket turbine blade and parts manufacturer, BSU focuses exclusively on producing new blading for all models of gas turbines, steam turbines, and compressors. Their commitment to precision engineering, in-house tooling, stringent quality assurance, and exemplary customer service aligns seamlessly with the values and standards set by RMS.

This strategic integration not only expands RMS’ capabilities but also provides our customers with access to the highest quality blades and a one-stop-shop for all their rotating equipment needs. BSU’s legacy customers will now benefit from RMS’ leading engineering and manufacturing infrastructure, ensuring an even more robust and comprehensive service.

Together, RMS and BSU are poised to elevate the standards of the turbomachinery industry, offering a unique blend of expertise, innovation, and customer-centric services.

A History of Blading Services

In the dynamic world of turbine manufacturing, precision is paramount, and Blading Services Unlimited, LLC (BSU) has been at the forefront since its inception on March 10, 2014. Founded with a vision to deliver unparalleled quality and service to the steam and gas industry, BSU specializes in the manufacture of turbine blades and parts, where exacting tolerances and immaculate finishes are not just standards but imperatives.

BSU operates on the principles of customer-centricity and technical excellence. Whether it’s fabricating parts from customer-supplied drawings or employing reverse engineering techniques, where a sample of the old part is utilized to craft new components, BSU ensures that each product meets the highest standards of precision and performance.

At the helm of BSU’s management team is Stephen Stevens, whose outstanding career in manufacturing spans decades. With a rich background that includes stints at prominent organizations like Elmar Locker of H & E Machinery, Inc., Stephen brings a wealth of experience in setting up and managing manufacturing facilities. His leadership has been instrumental in shaping BSU’s commitment to quality and innovation.

Stephen’s journey in manufacturing began as the Production Manager for Elmar Locker of H & E Machinery, Inc. in Ithaca, NY. Over nineteen years with the company, he undertook significant responsibilities, including setting up and managing a plant in Owego, NY, overseeing operations in Jakarta, Indonesia, and serving as Plant Manager in Auburn, NY. His tenure at H & E Machinery, Inc. provided him with invaluable insights into the intricacies of manufacturing operations, laying the foundation for his subsequent ventures.

After leaving H & E Machinery, Inc. in 2003, Stephen embarked on a new chapter, playing a pivotal role in the establishment of Steam Turbine Blading and Parts in Minden, Nevada. His expertise and leadership were crucial in steering the company toward success, cementing his reputation as a visionary in the turbine manufacturing industry.

Following his tenure at Steam Turbine Blading and Parts, Stephen continued his journey at Hartman Enterprises in Oneida, New York, where he continued to serve his customers with unwavering dedication. However, driven by a desire to create something truly exceptional, Stephen co-founded Blading Services Unlimited, LLC in March 2014, laying the groundwork for a new era of excellence in turbine manufacturing.

Michael Rose, BSU’s Production Engineer, complements Stephen’s leadership with his profound expertise in turbine engineering. Beginning his career at H & E Machinery, Inc. in Ithaca, NY, Michael honed his skills in turbine manufacturing before transitioning to on-site repair work at various power plants. His hands-on experience provided him with invaluable insights into turbine operations, laying the foundation for his pivotal role at BSU.

Michael’s journey in turbine engineering led him to serve as the Production Manager at Steam Turbine Blading and Parts in Minden, Nevada, where he further honed his expertise in manufacturing processes and quality control. Subsequently, he joined Stephen at Hartman Enterprises in Oneida, New York, where he played a key role as the Milling Manager, overseeing programming, engineering, and inspection of blade work.

As Stephen and Michael transitioned from their previous ventures to establish BSU, they brought with them a legacy of trust and reliability, earning the confidence of clients across the industry. Since its inception, BSU has continued to push the boundaries of turbine manufacturing, leveraging cutting-edge technologies and a relentless pursuit of perfection.

In a sector where precision is paramount and reliability is non-negotiable, Blading Services Unlimited, LLC stands as a beacon of excellence, driving the future of turbine manufacturing with passion, expertise, and a steadfast commitment to customer satisfaction.