In the face of growing environmental challenges, many industries continue to evolve and search for new ways to reduce the expulsion of harmful waste products into the atmosphere. Applications and opportunities involving the harvesting and recycling of waste gases continue to present themselves as industries push to refine and clean up their processes. This industrial push comes with its own set of challenges, however, especially when dealing with the harshness and inconsistency of waste gas materials. A customer approached RMS with such a challenge. In the face of a very difficult design problem, RMS was eager to work with the customer to develop a solution. The customer was attempting to use an industrial blower fan to blow waste gas products from a dirty process into a furnace where harmful components of the gas could be burned off and steam could be salvaged for energy. The industrial blower fan was subjected to very harsh process gases and operating conditions which exceeded typical standard operational requirements, including speeds closer to that of an industrial compressor. As a result, the customer was experiencing persistent failures and reliability issues with their existing blower fan design and was in dire need of something above and beyond a standard industrial blower fan.

RMS, with its rich history in engineering industrial compressors, was happy to help bring the customer’s blower fan design forward, closer to a more highly engineered compressor-like design. The effort gave birth to a new type of product lying somewhere in between the robustness of a compressor with the simplicity of a blower-fan. For RMS, this was an “all-hands-on-deck” effort. RMS would need to leverage its advanced engineering design capabilities, RMS SMMART tools, experience in rotating machinery, and cutting-edge modeling techniques to develop a new high-performance blower fan product to meet the tough operating requirements. RMS’ highly engineered approach combined with decades of experience designing rotating machinery for high-speed applications resulted in an innovative blower-fan design that met the customer’s operating parameters safely and reliably.

The customer contacted RMS after experiencing numerous blower fan failures during operation. In spite of several re-design attempts, the blower fan continued to face high vibration and would routinely trip offline. Subsequent redesigns added complexity and cost to the blower fan but didn’t provide a solution. In dire need of an immediate solution, the customer contacted RMS knowing they needed a highly engineered approach to fix their blower fan problem. They provided RMS with a host of vibration and process data along with P&IDs to evaluate. The customer also shipped their existing blower fan to RMS’s Houston shop for further engineering evaluation and dimensional analysis. The RMS engineering team had a challenging task at hand: they needed to approach the new blower fan design like a highly-robust engineered compressor but needed to be mindful of the cost and simplicity requirements of an industrial blower fan.

Figure 1 – Original rotor and bearings sent to RMS for inspection and evaluation

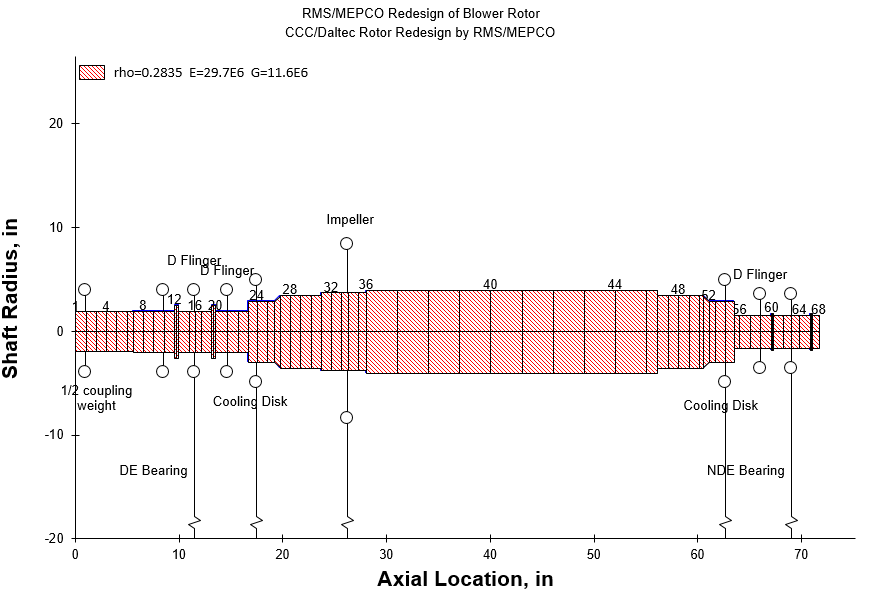

The first step for the engineering team was to develop an understanding of what had been done previously by the OEM and how RMS could correct deficiencies and build upon the strengths of the existing design. RMS made heavy use of its reverse-engineering capabilities to take on this task. Upon evaluating the initial design, it become very clear that several aspects of the design made it vulnerable to harsh operating conditions. The shaft design was complex, utilizing a multi-piece design with several welds. There was inadequate interference fits for several components onto the shaft, making the rotor susceptible to vibrations. The impeller itself was actually welded to the shaft in an attempt to compensate for an inadequate interference fit. This added additional stress concentrations and failure points to the design while increasing the overall design complexity and cost. The impeller hub design was actually hollow which introduced strength vulnerabilities and went against conventional compressor design practices. It became clear that an entirely new shaft and hub design was necessary. To develop a new shaft design, RMS engineers made use of rotor-dynamics analysis (RDA) tools. Utilizing RDA techniques in combination with previous experience, a more stable, one-piece, critically damped shaft system was developed for the application. A critically damped structure was preferred for this application inasmuch as it would respond to disturbances in a more favorable way: it would return to its initial state without excessive oscillations, leading to less shaft vibration.

Figure 2 – Rotor dynamics and critical speed map analysis of the new rotor design

Figure 2 – Rotor dynamics and critical speed map analysis of the new rotor design

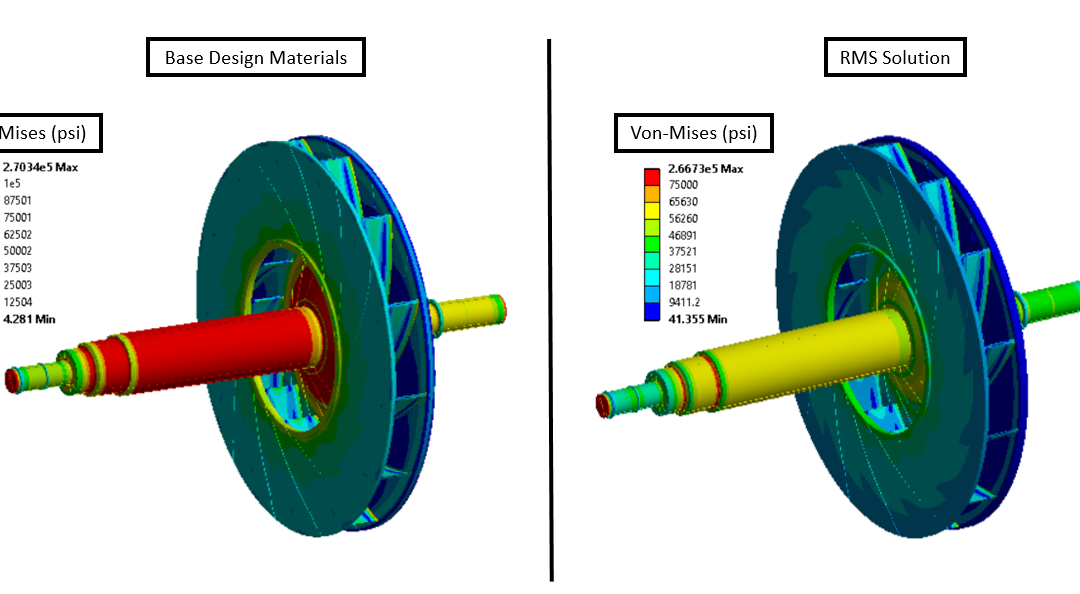

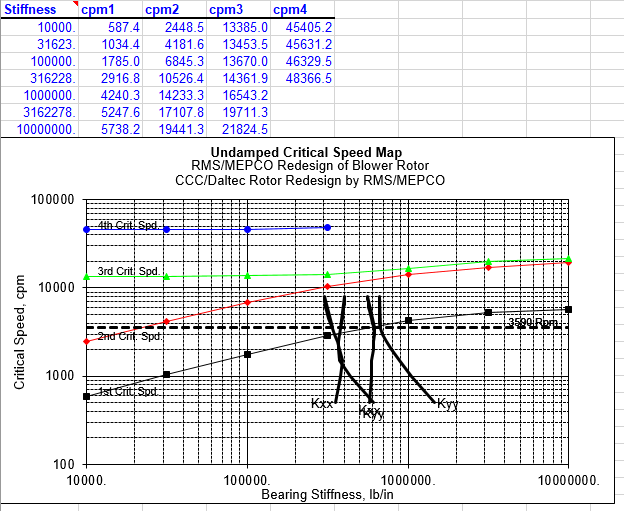

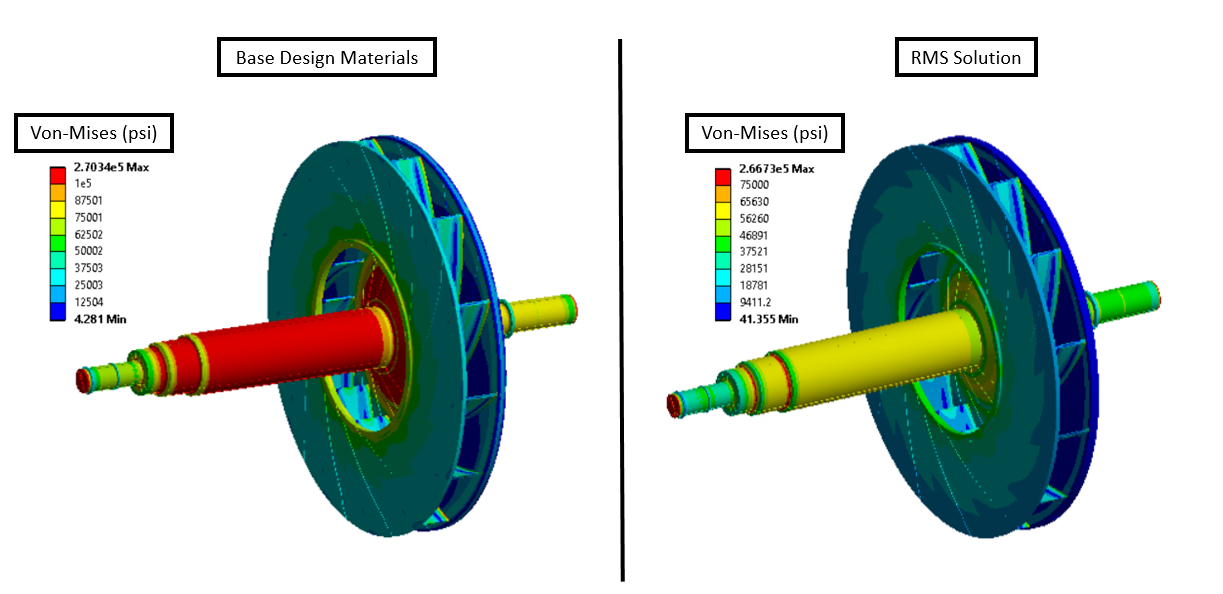

To take on the impeller re-design, RMS again made heavy use of its reverse engineering capabilities to develop a finite element model of the existing blower-fan. The engineering team combined finite element analysis with industry experience to identify weak points in the design and develop solutions for problematic areas. Again, there were many challenges as the engineering team needed to employ design techniques that were somewhere “in-between” a full industrial compressor design and a more cost-effective blower-fan design. The team went through several design iterations, which saw the introduction of upgraded materials and improved design principles to create a more stable blower-fan that was capable of reliable performance in the presence of a harsh environment.

Figure 3 – Proper material selection is a critical step in achieving success in high-performance applications. RMS uses state-of-the-art material selection for rotating machinery to ensure that the design is robust, even when subjected to harsh thermal and centrifugal forces. On the left, the high-stress areas are shown as red in the existing design. On the right: after some minor design tweaks and material changes, the red, high-stress areas are greatly reduced.

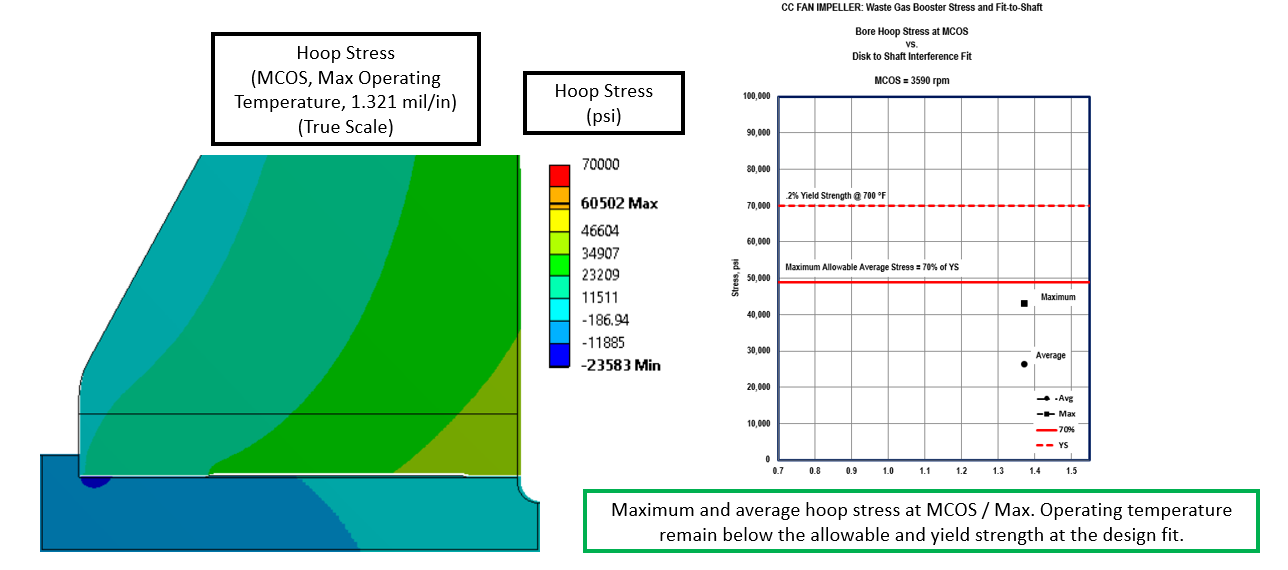

Another critical area was the hub design and the hub-to-shaft fit. Finite element modeling was again used heavily to develop a more robust, 1-piece solid hub design. The welds were removed and a hub-to-shaft interference fit using RMS’ tried and true fit analysis approach lead to a more robust and simplified design in the fit area.

Figure 4 – Due to high centrifugal and thermal loads, the hub experienced an elevated state of “hoop” stress. The elevated stresses immediately called for a stronger, solid hub design. The RMS 1-piece hub design in combination with high-strength materials ensured that the stresses remained below the material yield strength with acceptable safety factor.

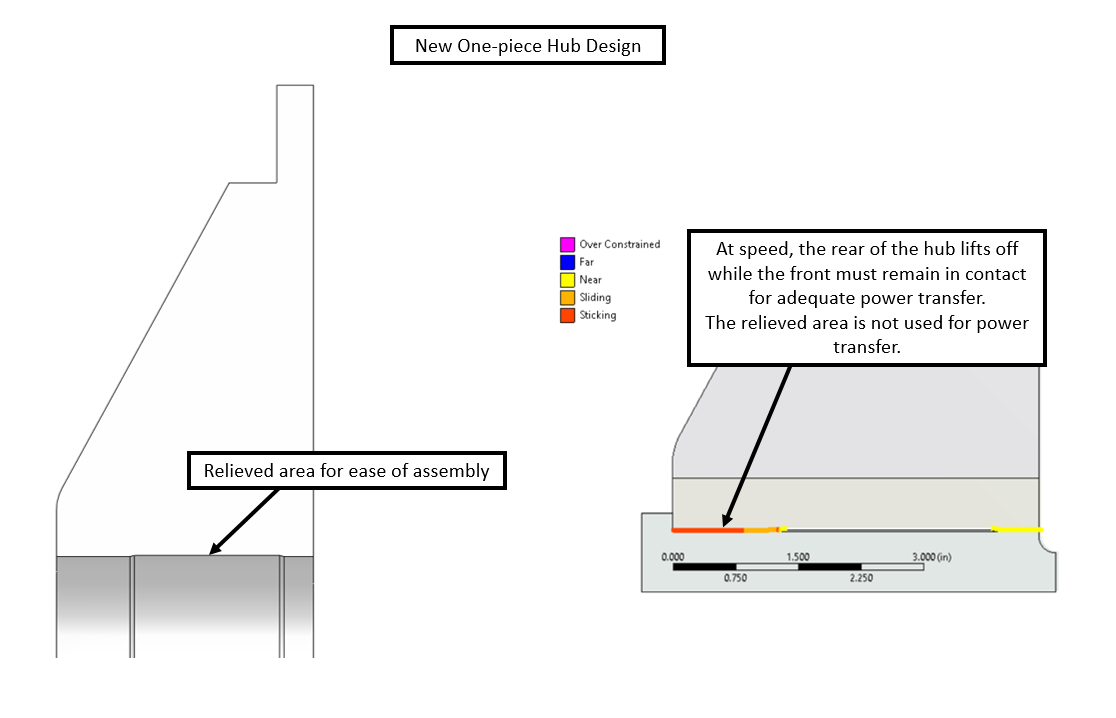

The RMS 1-piece hub design featured a “relieved” area in the center of the fit for ease of assembly when trying to fit the hub on the shaft. This relieved area was tailored to the application such that adequate power transfer was still maintained at the front of the hub fit when the heel lifted off at speed.

Figure 5 – Analysis of the fit showed how the “heel” of the hub lifted during speed operation due to centrifugal force. When using a relieved interference fit, it was critical to ensure that enough of the fit remained at the operating speed such that power was still adequately transferred from the shaft to the hub

As the design was finalized, it became clear that a new “hybrid” blower fan/centrifugal compressor prototype was born. Through the blending of high-tech centrifugal compressor design with simplified blower-fan design, RMS was able to develop a solution for the customer. The resulting prototype was not only more robust than the OEM design, but also more simplified with reduced manufacturing complexity and easier assembly. All of this was achieved while being mindful of the cost and reliability requirements desired by the customer. Improved materials introduced better thermal stability and a new hub design resulted in a blower-fan that was engineered and built with highly engineered solutions typically reserved for compressors and turbines.

RMS provided the first completed new prototype blower fan rotor to the customer, which is currently in operation. Following up on this initial shipment, RMS is providing three additional blower fan prototypes designed specifically to function in this customer’s unique application.

Do you have a unique application that calls for a novel approach? Are you experiencing persistent issues with your rotating equipment? Whatever the issue may be, RMS would be eager to help you on your journey. Give RMS a call and see how our experienced engineers can help.