By: Farzam Mortazavi, Senior Engineer

With the advent of digital technology and moving forward toward virtual engineering, it is more critical than ever to marry the concepts of inspection, design engineering, and analysis. The multi-function approach is an enabling technology to design engineering, above all other benefits, such as engineering economics. Virtual inspection, free-form design, and ad-hoc structural analysis are a few examples that allow the engineer to take the design to the next level.

As the saying goes, a picture is worth a thousand words. We’ll immediately delve into some examples to show how RMS leverages technology and the SMMART (Scanning, Measuring, Modeling, Analyzing, Redesigning, and Testing) approach in its turbomachinery engineered products:

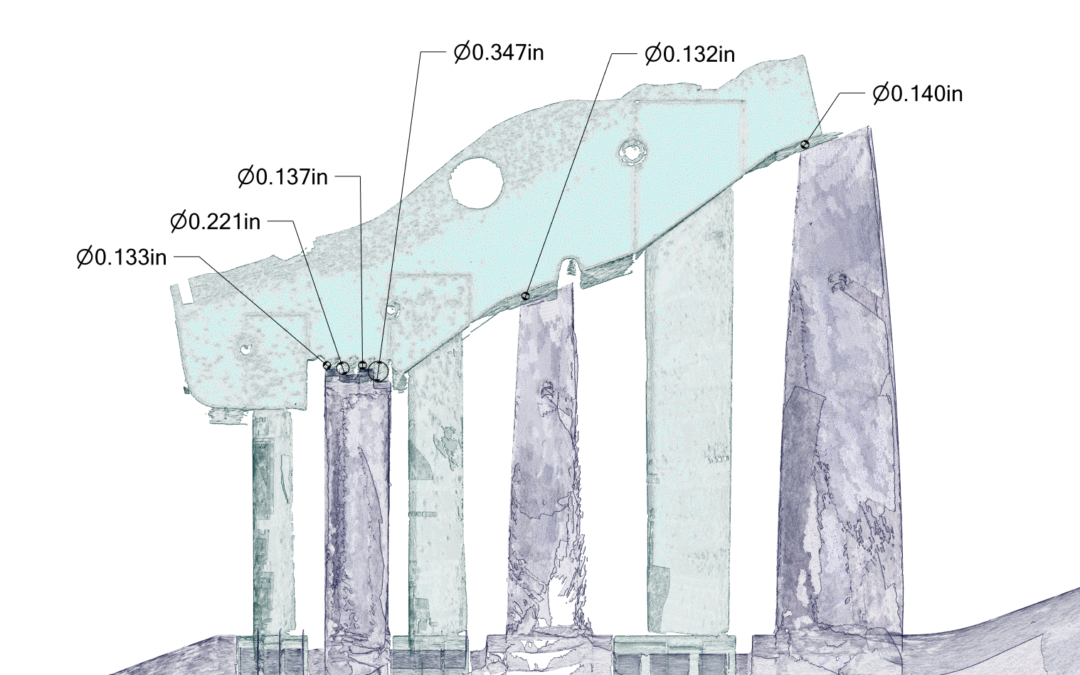

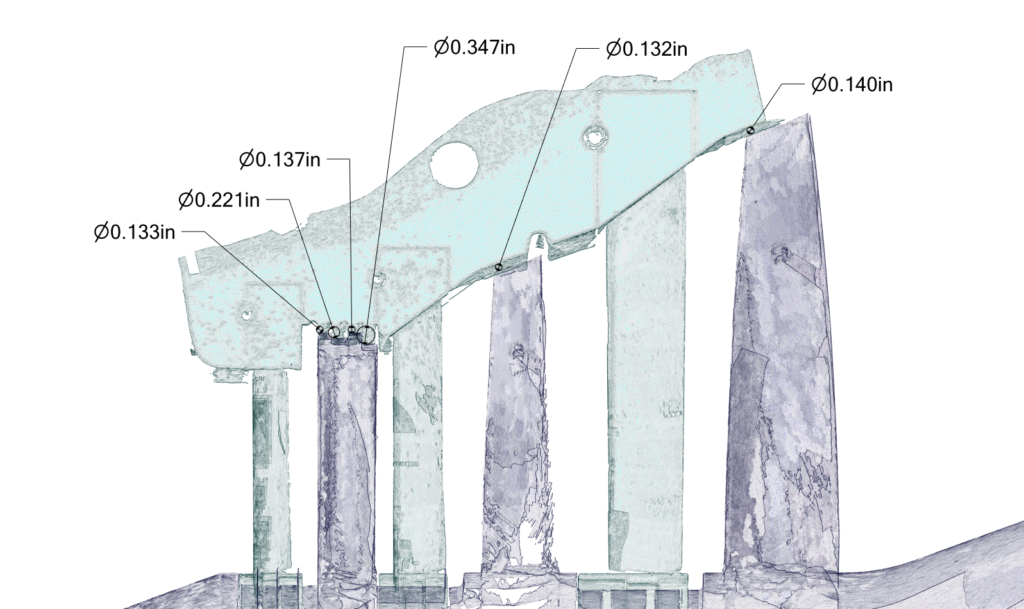

3D Scan and Virtual Inspection: Manufacturing and assembly tolerances often present challenges in inspecting all the required dimensions. By a 3D scan, a multi-part assembly can be virtually inspected by creating dozens of reference planes for standardized measurements. Here is an example of an entire lower half casing, seal and bearing housings, and pedestals of a steam turbine, coordinated for all connection locations. Note the best-fit flanges and bolt circles.

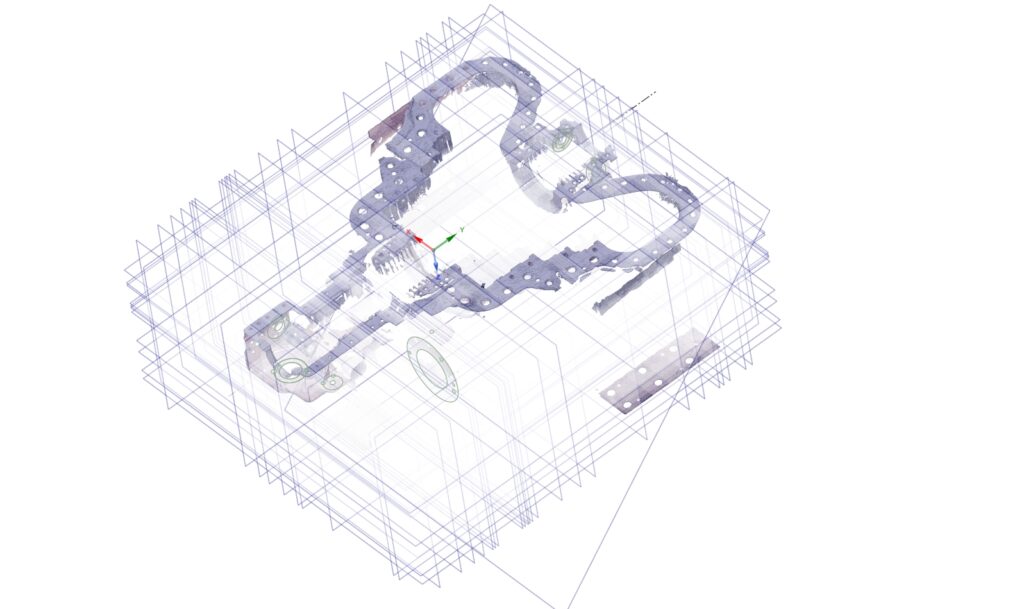

Virtual Testing: Engineers can do a quick fit-for-purpose analysis on reused parts without jeopardizing the part’s structural integrity. Here is an example of a “Virtual Hydrotest” directly created from scanned casings. The customer requested to verify a slightly higher MAWP for the exhaust casing. Cast casings are converted into “as-cast” 3D models using organic best-fit surfaces and passed to structural modeling for a quick hydro load case.

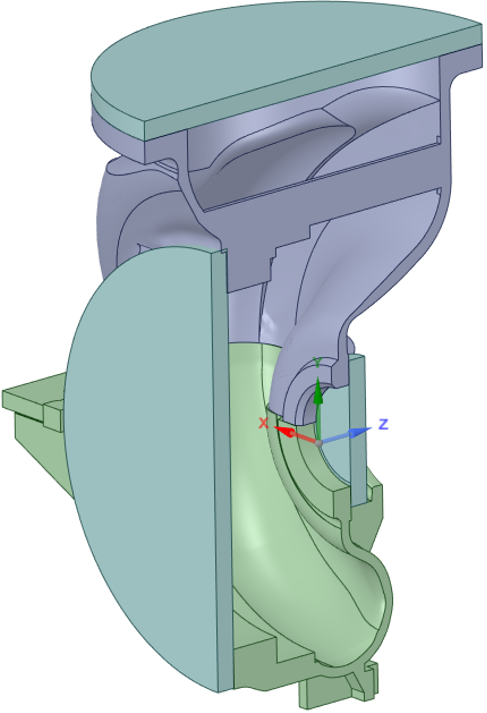

Fit Analysis: Frequently it is desired to rework and reclaim specific interference fits between new and existing mating parts without removing too much material. The figure below shows an instance where a fit analysis of a scanned existing bearing housing and an “as-designed” new journal defines the minimum material removal. The green areas show interference fits within tolerance, and the red color shows excessive shrink.

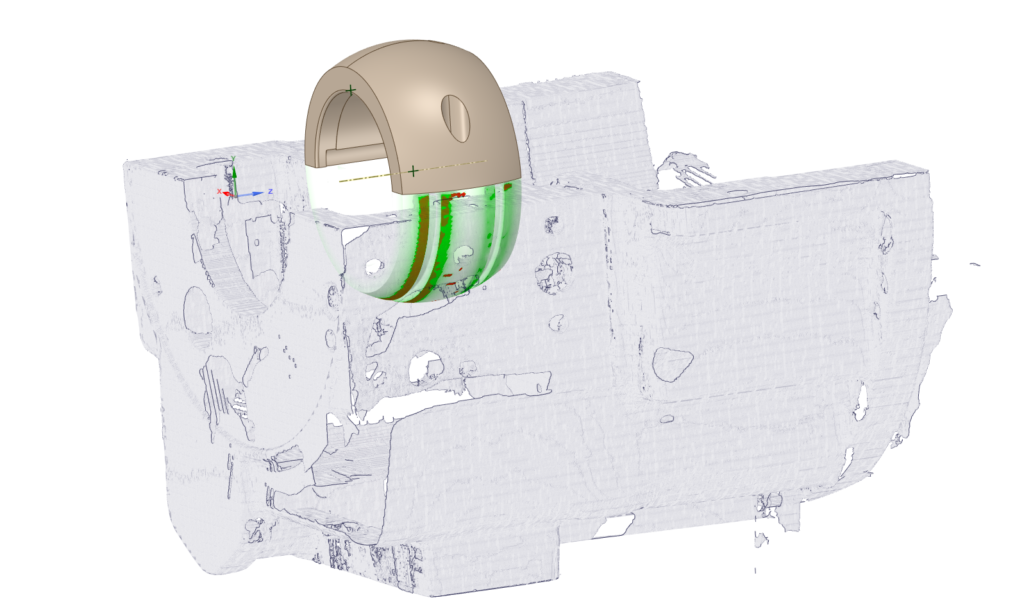

Virtual Assembly and Clearance Inspection: Accessing and measuring tight radial and axial clearances is always time-consuming and—in some cases—simply not possible. In many cases, the machine is already disassembled when the inspection team arrives. RMS adjusted blade tip clearance design by virtual assembly and inspection of tip clearances from the overhauled rotor and casing scan models.

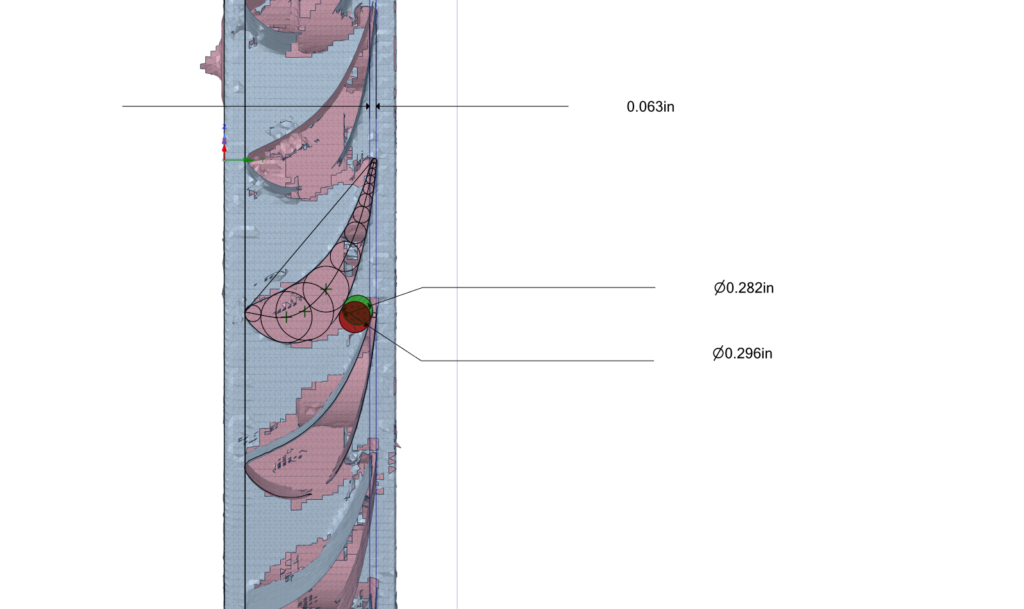

Uprate Potential: A popular technique in uprating steam turbines involves axially cutting back the nozzles to open the throats. The amount of cutback is usually limited to 1/16”-1/18”. New throats are obtained from the nozzle block scan in the feasibility study phase as input to the performance model. Below we see a roughly 5% increase in flow path area for this particular nozzle.

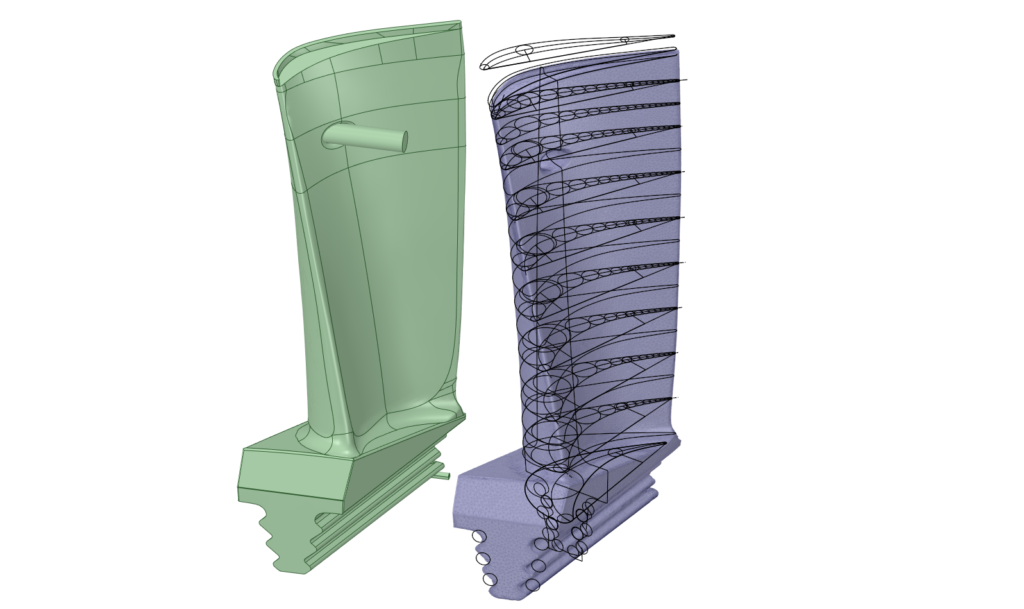

Scan to 3D CAD: Occasionally a single blade or two needs replacement. Since the blade profile is highly twisted and the airfoil profile varies from root to tip, conventional measurement techniques cannot be used to obtain the blade geometry. However, the blade geometry can be closely constructed with advanced 3D modeling capabilities and knowledge of how various surfaces are designed. The figures below show a blade for a power turbine with a surface deviation of less than 0.005” except at the squealer ring trailing edge where the blade was rubbed. The process was entirely done under an integrated 3D platform.

Conclusion: Future opportunities are arising from the ever-increasing computer memory and processing speeds and advancements in virtual tools’ accuracy and technology. In the near future, it will be possible and economical to perform micrometer-level inspections in a digital environment. Virtual inspection, where applicable, is less prone to human error and yields more repeatable measurements by unifying multiple instruments into one tool. RMS continues to invest and expand its inspection and design tools to offer modern, high-quality solutions to the turbomachinery industry.