RMS was recently contracted by a refining customer to undertake a critical project focused on replacing two riveted impellers for a centrifugal compressor in plant air service. Facing tight time constraints due to an impending outage, RMS and the customer decided to employ a state-of-the-art additive manufacturing process to 3D print the replacement impellers. The resulting impeller represents the largest and first-ever 3D-printed centrifugal compressor impellers used in a refining application.

This innovative approach allowed for a significantly reduced production duration, cutting lead times by 50% compared to traditional manufacturing methods. Leveraging the expertise of RMS’s metrology team and advanced engineering resources, the team thoroughly designed and manufactured the impellers.

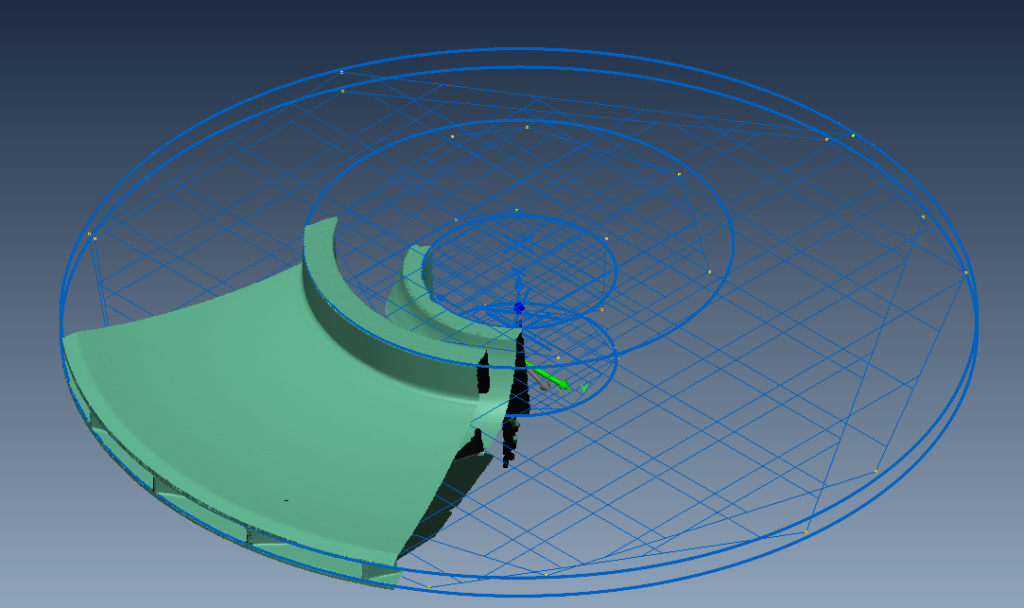

The project presented several challenges. The existing impeller design used a riveted construction and measured 23.5 inches in diameter. However, the largest printing bed available for a 3D-printed impeller was limited to a 23-inch diameter. To address this, RMS engineers needed to redesign the impeller geometry to overcome the reduction in head that would naturally occur from decreased diameter. RMS’s Aero team designed the impellers to achieve the customer’s performance requirements and did not simply duplicate the riveted impeller geometry.

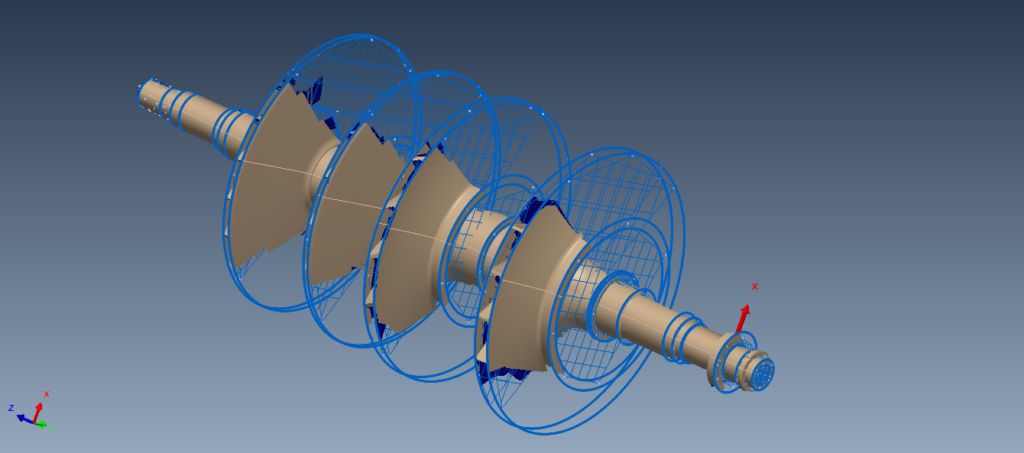

Extensive engineering was required to ensure that the new impellers would deliver comparable performance despite their reduced size. The high tip speeds required for the impellers (>1000 ft/s) necessitated careful evaluation of stresses to ensure reliable operation. RMS’s Analytical Team conducted comprehensive modeling activities, including full structural and aerodynamic analysis using CFD, to ensure the new designs met the customer’s stringent process requirements.

RMS worked meticulously to develop an impeller design that leverages the design freedom afforded by the 3D printing process. The impellers featured shallow cover angles of 3.8 degrees for the stage 3 wheel and 2.5 degrees for the stage 4 wheel. The impeller was manufactured using Inconel 718 and the latest API 20S Standard, a material known for its exceptional strength and durability. This choice of material resulted in a final product that was significantly stronger and more reliable than the previous riveted impellers, ensuring superior performance for the refineries’ application.

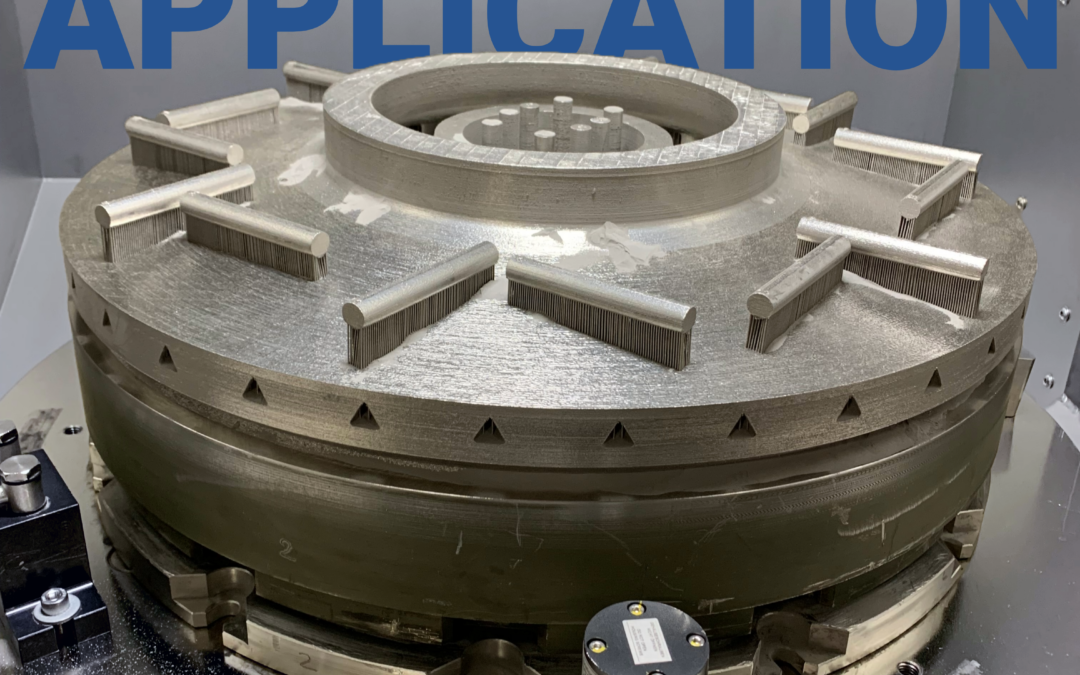

The 3D printing process employs a series of lasers to build the impellers layer by layer from a powdered bed fusion of Inconel. This comprehensive manufacturing process ensures a uniform final product ready to perform in the field.

To guarantee the performance and reliability of the 3D-printed impellers, multiple test bars were produced during the printing process. To ensure quality in all directions, test bars were printed from each laser, and oriented in each axis to ensure consistent quality in all directions. These test bars underwent rigorous testing to confirm that the metal met all necessary performance standards. This comprehensive manufacturing process and series of protocols were paramount in validating the new impeller manufacturing process, demonstrating RMS’s commitment to innovation and quality.

The result was groundbreaking: RMS delivered two 3D-printed impellers that were not only a first for the customer’s compressor fleet but also a testament to the capabilities of modern manufacturing techniques. This successful collaboration highlights RMS’s commitment to cutting-edge technology and our ability to provide tailored solutions under tight deadlines, ensuring operational efficiency and reliability for our clients