RMS recently worked on the development and testing of a 3D printed covered impeller to better serve our customers. RMS’s continuous use of cutting-edge technology to improve customer outcomes lead the engineering team to explore the use of advanced 3D printing solutions. The team at RMS partnered with industry leading additive manufacturer Velo3D to develop and print a covered disc impeller. The resulting product significantly reduced production time compared to traditional methods while giving customers a stronger product thanks to the use of Inconel 718. The ability to 3D print impellers backed by RMS’s proven engineering opens up a new world of possibilities for our customers. RMS can now deliver Inconel 718 covered impellers with reduced manufacture lead times to reduce customer down time and cut project durations.

Project Overview

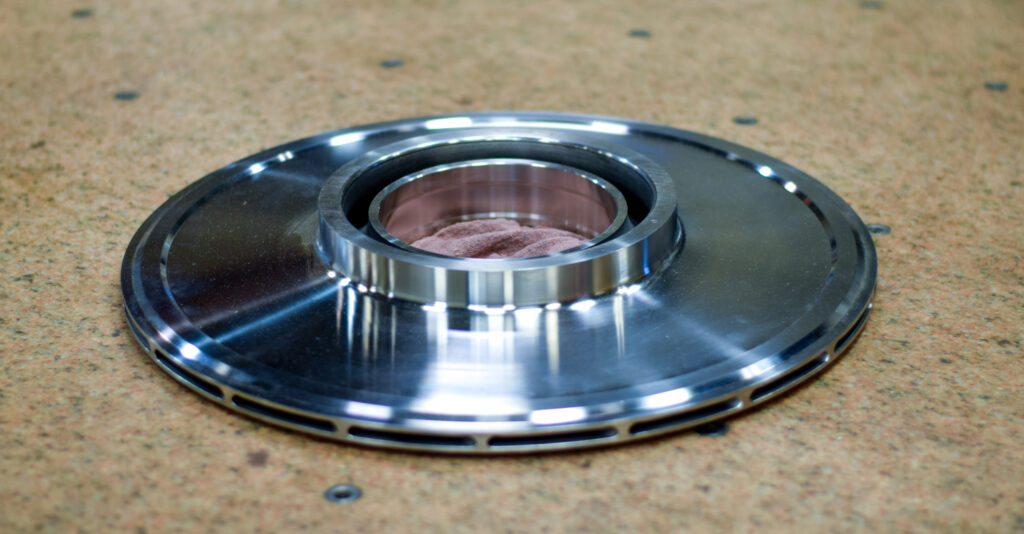

RMS started its evaluation of metal AM (Additive Manufacturing) technology by working with Velo3D and contract manufacturer Duncan Machine Products (DMP) to assess the use of metal AM to produce a small Ø 10.7” Inconel 718 shrouded impeller, manufactured without internal support structures. Overspeed testing at 16449 rpm (115% of operating speed) was the chosen method of evaluation.

Initial testing to industry standards was successful, and the impeller was further tested to 25,000 rpm with the impeller displaying high resilience, no distortion or NDT indications. However, many of RMS’s projects involve larger impellers. Unfortunately, most conventional metal 3D printing technology today cannot produce a part in the size and scope required by RMS core business needs. This limitation drove the company to assess shrouded impellers achievable only with the large-format Sapphire XC metal 3D printer, one of only a handful of metal 3D printers with a 600mm Ø build area.

III. The Challenge and the Innovation

The new project targeted the successful spin testing of a large, shrouded impeller requiring minimal post-processing. The impeller, made from Inconel 718, had a 19” diameter (483mm) with a 2-degree (near flat) ceiling. The primary challenge was the impeller’s large span features and low overhang angles, with only 9/32 (0.288) in (7.3 mm) access to remove any support structure from an area that measured 4.7” x 3”. The first exploratory impeller was the largest and shallowest impeller ever attempted at greater than 500 mm (about 1.64 ft) scale.

During the transition to this larger size, risk mitigation builds were executed to appraise the processes on more extensive spans. Through risk mitigation builds, the team determined that when printing at this scale, low angle impellers can experience a greater amount of melt pool instabilities (MPIs) that lead to small metal ‘stalactites’ forming on the upper shroud. MPIs can occur on downskin surfaces where the printer attempts to melt metal onto a powder substrate. If the laser delivers too much energy, this extra heat melts more material than desired and results in a metal sphere that forms on the underside of the overhang. MPIs can be difficult to remove from inaccessible places leading engineering to find novel solutions.

Results

To overcome this challenge, RMS worked with Velo3D engineers and initiated internal development to design a support strategy that could retain surface quality while also being easily removable. Through a Design of Experiments (DOE) conducted on several overhang test coupons and sample impeller geometries, tapered pin supports were found to be easy to remove and provide the best surface quality. With the new pin supports, the build was completed by Velo3D with post-processing by contract manufacturing partner Knust Godwin. The processed part underwent a series of post-processing steps including stress relief, heat treatment, machining, solution, and ageing heat treatment.

The completed impeller met RMS’s rigorous quality specifications for the inspection and approval of an impeller build. RMS conducted extensive dimensional and NDT inspections to verify the quality of this new impeller production process. Following completion of heat treatment and final machining, the impeller will be NDT and dimensionally inspected prior spin testing at 115% overspeed (9737 rpm) to verify that at speeds and stresses higher than the part would see in service that no distortion occurs, and no cracks form.

Tensile testing of specimens printed and heat treated with the impeller exceeded the strength required per ASTM F3055-14a. The build time clocked 62 hours (about 2 and a half days) and the internal supports were minimal. Meanwhile, the MPIs were significantly reduced, allowing for easy removal of the internal pin supports without any special processes.

Total manufacturing time, including printing and all post-processing and machining operations, required less than half the time needed to manufacture the same impeller through conventional methods. Reach out to your RMS sales rep to learn more about how RMS can support your critical rotating equipment needs with cutting edge 3D printed solutions.