After the scanning is complete and the data is collected, the RMS Metrology team begins work on the creation of digital twins. Digital twins are files of scanned machines and components that RMS stores in a controlled environment. These 3D scan files assist with the assembly of machines, prepare for future inspections, and even plan upgrades and rerates before future overhauls.

At the start of a project, the RMS Metrology team scans a machine to catalog critical data regarding the fit, critical clearances, and condition of a machine. This work can be done in the field or the shop depending on the project, but the impactful results remain the same. With this data, the RMS Metrology team can support both the engineering and shop to assist with an expedited inspection and then reassembly of the machine to meet customer requirements.

The digital twin is stored in RMS’s controlled filing system for future reference. When this same machine returns for its next overhaul, the scan data of the current condition is compared to the previous model. This allows the RMS team to quickly identify machine wear patterns caused by its most recent service run for expedited inspections. This precision data also allows for a detailed report showing the exact locations and dimensional data of complex wear patterns.

Digital twin data also allows for upgrades and rerates while a machine operates. The digital twin of a machine contains all of the critical dimensional data allowing RMS’s engineering team to create bespoke upgrades without the need to shut down mid-run.

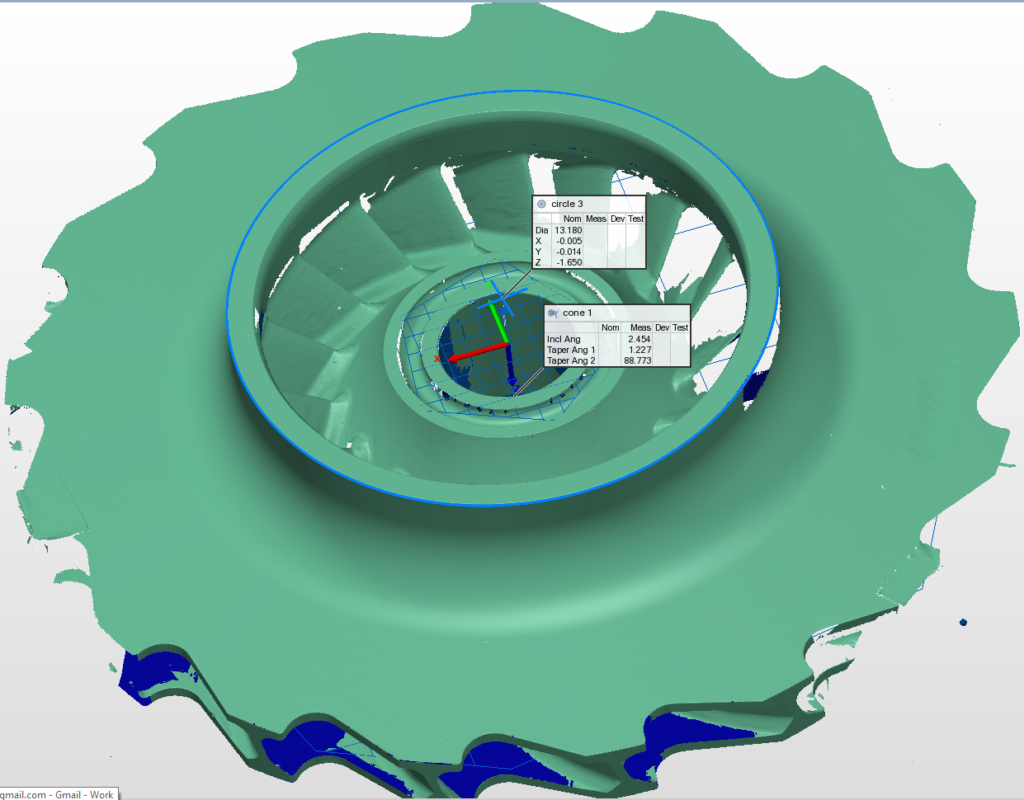

digital twin of impeller

The critical historical database of digital twins allows for a complete record of a machine through every phase of its operating life. This detailed record allows for predictive overhaul plans based on past machine wear patterns and the ability to assemble quicker thanks to detailed clearance data.

To learn more about digital twins for your machinery, reach out to your RMS sales rep to see how digital twins can support your machinery.Digital twins shift the paradigm for the entire turbomachinery industry and RMS is here to support the migration towards digitization of critical rotating equipment assets.