By: Matthew Williamson – Operations Manager Metrology

In refinery operations, thermal growth isn’t always visible—but its impact can be massive. Subtle movement during startup can lead to unexpected misalignment, accelerated wear, or even premature failure across critical rotating equipment.

That’s exactly what RMS uncovered during a scheduled turbine overhaul at a major processing facility, where what began as routine support revealed something deeper: a growing alignment issue tied to thermal expansion in the turbine-compressor train.

By transforming a standard alignment call into a thermal growth study, RMS worked closely with site stakeholders to track equipment movement using high-resolution 3D scans—delivering insights that enabled better decisions, improved reliability, and reduced future risk.

Precision Begins with Perspective

Having already completed preliminary scan work for the turnaround event, RMS technicians returned to the site to install epoxied monuments on key components and foundation points. These served as repeatable targets for high-precision measurement in both cold and hot operating conditions.

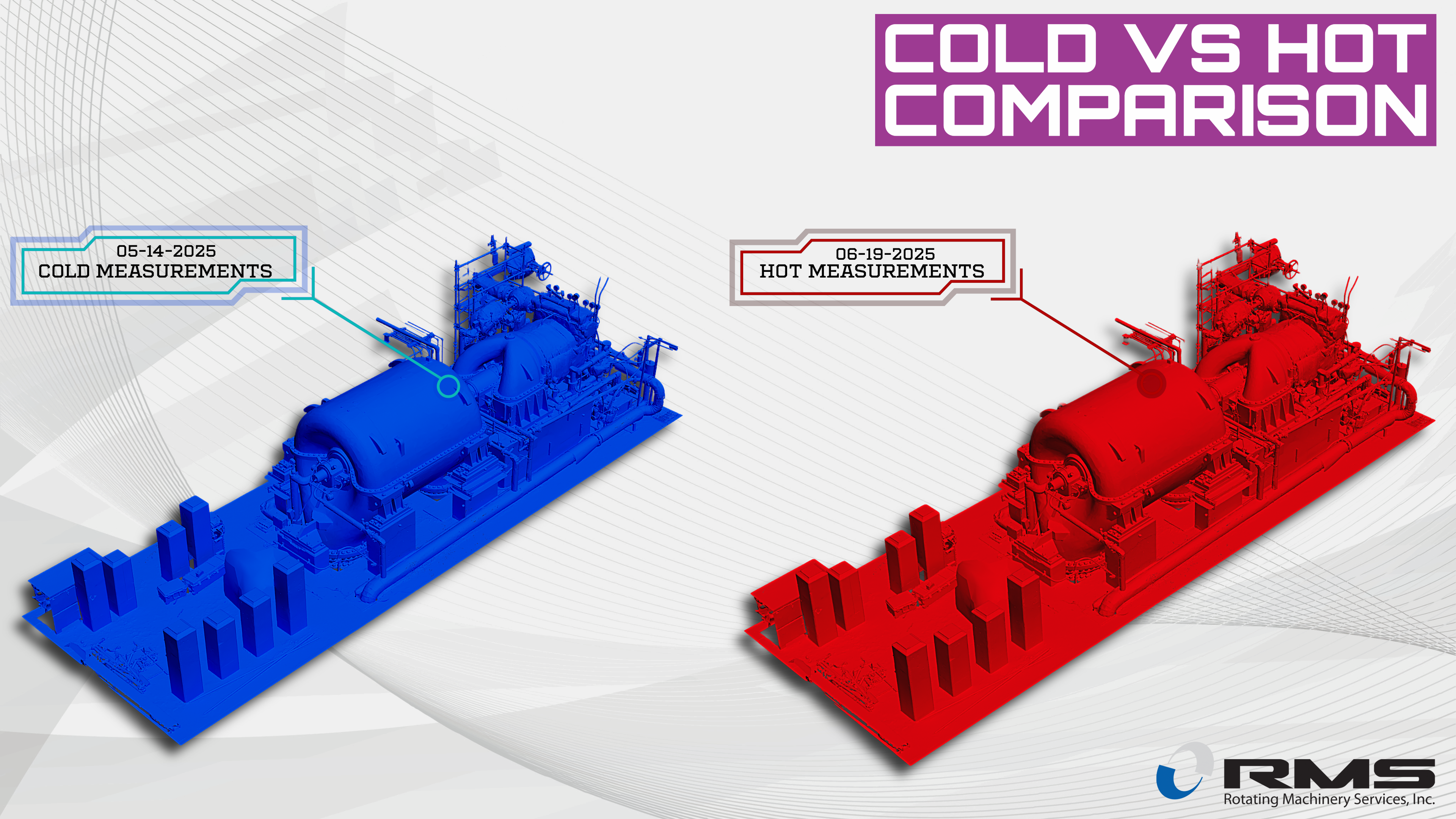

Using AT960LR laser tracker technology, RTC 360, and Polyworks software, the RMS team performed two full 3D scans:

- Cold Scan:May 12–15, 2025

- Hot Scan:June 17–20, 2025

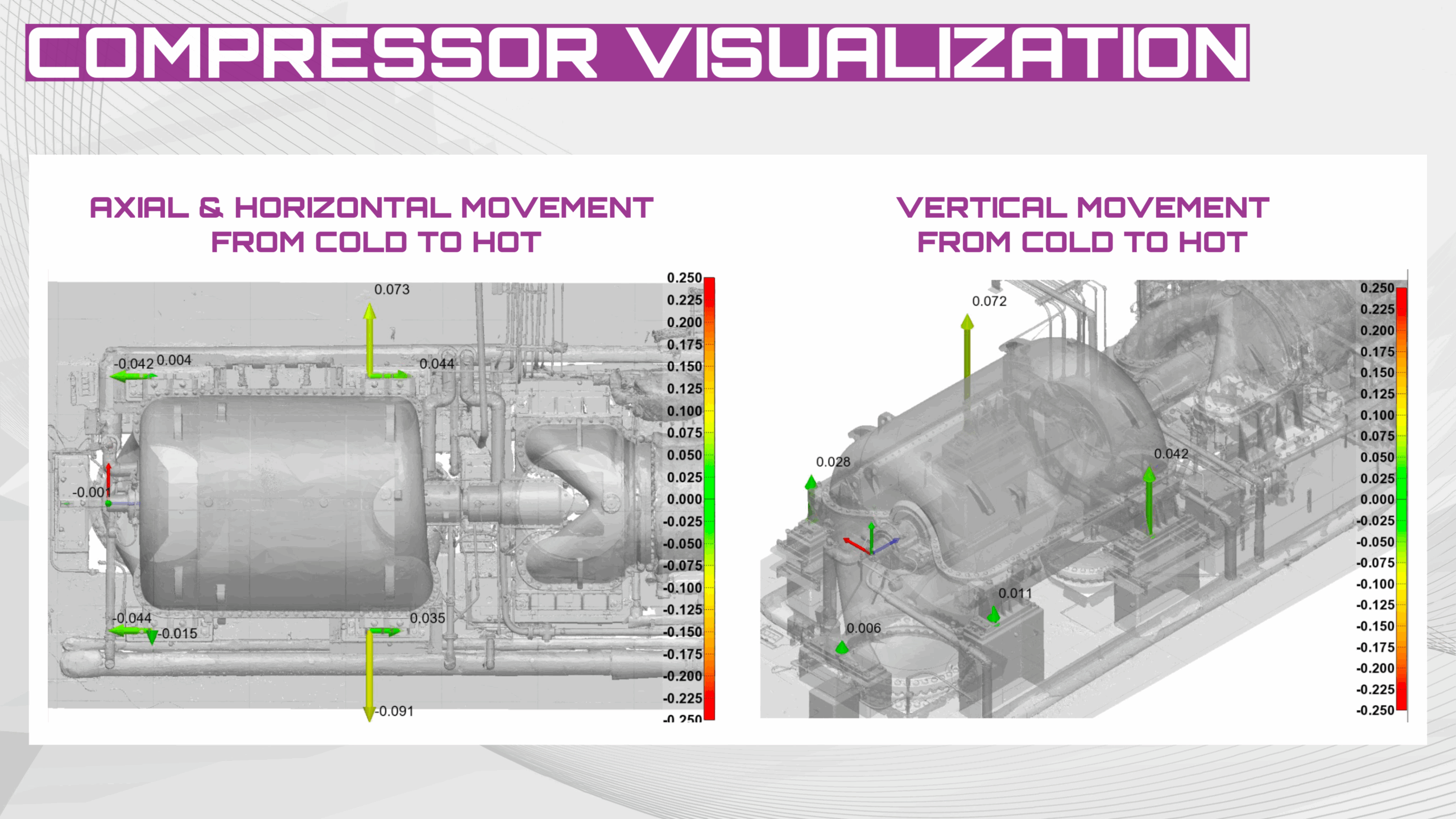

All measurements were aligned to a fixed concrete baseline, enabling accurate comparison of movement along the X, Y, and Z axes. Initial findings supported field observations, and additional analysis is underway as part of a broader study to observe thermal behavior across multiple ambient conditions and site visits.

Beyond the initial hot and cold scans, RMS will continue returning to the site to track potential changes over time—particularly in relation to ambient temperature shifts and possible foundation movement. This ongoing monitoring effort will help identify structural trends, such as degradation in concrete columns or misalignment driven by external factors. By expanding the scope from a two-part inspection to a multi-phase study, RMS is helping the site build a roadmap toward long-term structural clarity.

Uncovering the Unexpected

While initial assumptions pointed to compressor movement, the data told a different story: the turbine exhibited significantly more displacement during startup. This challenged prior expectations and underscored the value of measurement over assumption.

Even though cold alignment values appeared within specification, hot-state displacement suggested a deeper issue—likely involving the foundation or structural supports. By validating these hunches with precise thermal data, RMS helped shift the focus from surface-level alignment to long-term structural insight.

Turning Insight Into Action

This thermal growth study didn’t just solve an isolated issue—it laid the groundwork for ongoing reliability planning. RMS is now working with the site team to explore future monitoring solutions that will track structural behavior over time and help prevent future misalignment events.

It’s part of a broader shift in maintenance strategy: leveraging real-world data to drive smarter, more resilient decisions.

Bringing Clarity to Complexity

At RMS, thermal growth studies aren’t just about collecting numbers – they’re about uncovering patterns, validating assumptions, and revealing the deeper forces shaping alignment over time.

This is just the first step. Each visit, each data point, contributes to a broader understanding of how ambient conditions, structural behavior, and foundation dynamics influence system performance. What started as a two-part inspection is now evolving into a long-term study—designed to track changes over time and support future decision-making.

As the dataset expands, so does the ability to detect emerging issues—and act before they impact reliability.